Lifting hook

Lifting hook

Grab bucket

Grab bucket

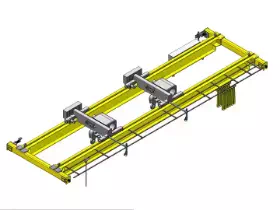

The QD hook bridge crane, a widely used lifting machine, primarily consists of a bridge structure, crane travel mechanism, trolley, and electrical systems. Its key feature is the hook as the load-handling device. The standard configuration is a double-girder design comprising a welded box-section main girder, end carriages, a hoist trolley with lifting and traversing mechanisms, and a complete electrical control system.

Rails are laid on the main girders for the trolley to traverse. The main girders are welded to box-shaped end carriages, which feature bolted joints at their midpoints to facilitate segmented transportation. A platform is installed for mounting electrical equipment and provides maintenance access. A full-view cabin is suspended beneath the main girder, housing a combined or separate control desk. Access is provided via a side ladder connecting the cabin to the platform.

Operation & Control:

Three operation modes are available: pendant control, wireless remote control, and cabin control. Cabins come in open or enclosed types, equipped with an adjustable seat, insulated floor mat, toughened glass windows, and essential safety items like a fire extinguisher. Optional accessories include an air conditioner, audible alarm, and intercom.

Key Features:

A robust heavy-duty structure designed for reliable performance.

Smooth acceleration and deceleration during operation.

Safe, reliable travel mechanisms with long service life.

Low-noise operation and a spacious cabin with excellent visibility.

High-quality automatic welding with non-destructive testing (NDT).

Crane drive motors rated IP54/IP44 with Class F insulation.

Customizable design based on specific project requirements.

Safety Features:

Overload protection system.

Emergency braking function.

Main hoist motor with thermal and current protection.

Hooks equipped with safety latches.

Rubber buffers on end carriages.

Limit switches for both travel and lifting motions.

All cranes undergo full factory testing and are supplied with a test certificate.

Customization & Support:

We offer customized designs. Providing detailed specifications such as lifting capacity, span, lifting height, voltage, working conditions (material, temperature), and travel distance enables us to create an optimal solution. Plant layout drawings are helpful for precise planning.

It is suitable to work in factories, warehouses and freight yards where the ambient temperature is-10℃-40℃ and the relative humidity is not more than 85%. It is prohibited to work in the environment with inflammable,explosive and corrosive gas. The crane can be furnished with load handling devices such as motor grab, electromagnetic chuck to meet the requirements of hoisting varied types of materials.

This equipment is widely used in hoisting operation.

For example, factory, mines, transport materials in the fix span scope, mechanical processing workshop, metallurgical factory and subsidiary workshop, warehouse, material yard and power plant.